POLYCARBONATE CORRUGATED

Leading Cutting Edge Plastics 100% Virgin Grade

POLYCARBONATE CORRUGATED

POLYCARBONATE TRANSPARENT ROOFING SHEETS

POLYCARBONATE TRANSPARENT ROOFING SHEETS

![]() brand of Polycarbonate transparent roofing sheets are manufactured from 100% virgin grade resins from world renowned producers such as Covestro, Chimei, Bayer, Sabic.

brand of Polycarbonate transparent roofing sheets are manufactured from 100% virgin grade resins from world renowned producers such as Covestro, Chimei, Bayer, Sabic.

Our processes and utilization of high grade materials ensures consistent quality and performance, every time, without compromise.

“100% VIRGIN GRADE RESINS ONLY”

ADVANTAGES OF USING  POLYCARBONATE TRANSPARENT ROOFING SHEETS

POLYCARBONATE TRANSPARENT ROOFING SHEETS

Superior Tensile Strength

![]() Polycarbonate transparent roofing sheets offers superior tensile strength and durability. The base material is the same used for ballistics and bullet proof panels!

Polycarbonate transparent roofing sheets offers superior tensile strength and durability. The base material is the same used for ballistics and bullet proof panels!

Clarity and radiation filtering

![]() Polycarbonate transparent roofing sheets offers high transparency, which allows maximum amount of natural light while providing effective protection against harmful ultra violet rays.

Polycarbonate transparent roofing sheets offers high transparency, which allows maximum amount of natural light while providing effective protection against harmful ultra violet rays.

Thermoformability and easy installation

![]() Polycarbonate transparents roofing sheets can be hot or cold bent. As such they can be curved to suit various design requirements. Relatively light weight, they can be easily installed at height without incurring excessive labour costs.

Polycarbonate transparents roofing sheets can be hot or cold bent. As such they can be curved to suit various design requirements. Relatively light weight, they can be easily installed at height without incurring excessive labour costs.

Energy saving: for a greener future

![]() Polycarbonate transparent roofing sheets conserves energy by cutting lighting costs significantly, with little initial investments. Greater savings, greater productivity.

Polycarbonate transparent roofing sheets conserves energy by cutting lighting costs significantly, with little initial investments. Greater savings, greater productivity.

Product Specification

100% Virgin grade resins, with in-built UV inhibitors

Weather resistant, high durability, good inpact resistance

UV filtration up to 99%

Application

General Warehouses

Commercial spaces

Residential skylights

Sports complexes

INSTALLATION GUIDE

INSTALLATION GUIDE

Handling and Storage

Transport and storage Vermax® Polycarbonate Transparent Roofing Sheets horizontally on flat.

Avoid storing unwrapped Vermax® Polycarbonate Transparent Roofing Sheets.

Short Vermax® Polycarbonate Transparents Roofing sheets should be stacked on top of longer ones. Do not stack up more than 1 meter in height.

Store Vermax® Polycarbonate Transparent Roofing Sheets in a cool, dry and shaded place, protected from direct sunlight.

Recommended handling:

Protect the sheets from any physical damage.

Avoid stepping on the panel when it on the ground.

Avoid folding panels across the corrugation during handling and installation.

Do not drag the Vermax® Polycarbonate Transparent Roofing Sheets on the ground or scrape them against structural elements or other rough objects.

Processing

Cutting

Use fine-toothed tenon saw.

Power saws with abrasive cutting-off wheel or circular saw blade suitable for cutting Vermax® Polycarbonate Transparent Roofing Sheets with dark or

Jig saw with suitable blade may be used as well.

Drilling

a) Pre-drill the required fixing holes to at least 4-5 mm larger than the diameter of the screw used. (e.g. Diameter of screw 4mm, hole drilled required minimum 8mm or larger)

b) Power drill may be use at LOW SPEED and the drill bit must be ground to suit the Vermax® Polycarbonate Transparent Roofing Sheets with dark or

Avoid drilling hole punching.

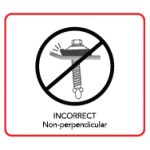

Drilling vertically at 90°

Roof Details

Pitch

The minimum recommended roof pitch for Vermax® Polycarbonate Transparent Roofing Sheets application is 6° (10% slope).

For roof pitch less than 10° (1:5.6) apply full sealing system (Neutral Silicone Sealants) on all lapping and drilled holes.

Purlins

Roof purlins must have a level face parallel to the Vermax® Polycarbonate Transparent Roofing Sheets.

The allowed maximum roof span (purlins distance - center to center) is 1.2 meter.

Positioning

Lay the Vermax®Polycarbonate Transparent Roofing Sheets to overlap the metal roof panels on both sides. If not feasible - Vermax® Polycarbonate Transparent Roofing Sheets must underlap the metal roof panels side against the primary direction of wind/rain.

Vermax® Polycarbonate Transparent Roofing Sheets must be located and installed without any stresses. Do not pull, stretch or force the sheets when the profiles are not perfectly matched.

Overlaps

Recommended longtitude overlap of minimum 300mm above purlin.

Each Vermax® Polycarbonate Transparent Roofing Sheetsto extend 150mm or over the fixings along the purlin.

Recommended apply two runs of sealing (Neutral Silicone Sealants) on both sides of fasteners line.

Side-laps

Recommended apply sealing (Neutral Silicone Sealants) along the centreline of the corrugation ribs

Vermax® Polycarbonate Transparent Roofing Sheets must be located and installed without any stresses. Do not pull, stretch or force the sheets when the profiles are not perfectly matched.

Fastening

Pre-drill 8mm or more holes at the screw points.

Fasten screws on every purlin from the lower end towards the upper end sequentially, starting always from the same side.

Always fasten through the ribs of the Vermax® Polycarbonate Transparent Roofing Sheets. Do not fasten screw on the valley.

The screws should be tightened moderately, without deforming the washer and distorting the Vermax® Polycarbonate Transparent Roofing Sheets. Careful attention should be given to assure perpendicular insertion of the fasteners.

Excess tightening and oblique insertion will distort the Vermax® High-Impact Acrylic Transparent Roofing Sheets induceundue internal stresses, leading to fracture and cracks, eventually ending in failure.

Screws fasten positioning vertically at 90°. Screws fasten position at the center of the pre-drill hole and not the side or corner of the pre-drill hole.

Do not fasten screw at the side or corner of the ribs.

Never use an impact wrench or driver for fastening Vermax® Polycarbonate Transparent Roofing Sheets. Tighten by handor by an adjustable torque power screwdriver

Do not use Drive Screw' Nails or Pop Rivets. 6. Fastening

TECHNICAL ADVICE:

If you are doubtful over the fixing and installation method, please contact our Project Technician or Marketing personnel for proper advice and assistance.

MANUFACTURER’S LIABILITIES:

The information contained in this brochure is to our best knowledge, accurate and proper, but all the recommendations are made Without Guarantee. Since the conditions of use at work site are beyond our control, we therefore Hold No Liabilities for any mishandling and workmanship defects in using our skylight materials.

PROJECT REFERENCE

Capsquare

Dang Wangi KL

Capsquare

Dang Wangi KL

Capsquare

Dang Wangi KL

Capsquare

Dang Wangi KL

Warehouse at Puncak Alam

(Fire Rated Polycarbonate Sheet)

Warehouse at Puncak Alam

(Fire Rated Polycarbonate Sheet)

Warehouse at Puncak Alam

(Fire Rated Polycarbonate Sheet)

R&R Ayer Keroh

R&R Ayer Keroh

SOLARTUFF CORRUGATED POLYCARBONATE

Nothing Beats Solartuff in Clarity and Durability

SolarTuff® is the premium corrugated polycarbonate sheet with superior transparency and toughness, absolutely the perfect roofing and glazing solution to your architectural needs.

Engineered with the most advanced European technology and selectively the best grades of plastic resins, SolarTuff® comes in lightweight yet virtually unbreakable characteristic, qualifying itself to withstand severe weather condition and unpredictable climate changes.

On top of it all, easy installation, high design flexibility and various attractive colors make SolarTuff® the perfect roofing and glazing secret to express your unique design and architectural creativity and imagination.

| Product Range |

|

| Profile Range |

|

| Key Properties |

|

| Application |

|

UV Safe

Besides protecting the people underneath from the harmful UV rays, the co-extruded UV layer on SolarTuff’s surface enhances its durability outdoor, preventing it from getting yellowing or discolored and brittle for a long period of time.

Light & Heat Transmission

| Light Transmission | Heat Transmission | |

| Roma |

|

|

| Greca |

|

|

Standard Sizes

| Thickness (mm) |

Width (mm) |

Effective Width (mm) |

Height (mm) |

Lenght / Customized (mm) |

|

| Roma | 0.8 | 860 | 760 | 18 | 1800, 2400, 3000, 3600, 4200, 6000 |

| Greca | 0.8 | 820 | 760 | 18 | 1800, 2400, 3000, 3600, 4200, 6000 |

| Trimdek | 0.8 | 830 | 762 | 29 | 6000 |