FIBERGLASS REINFORCED POLYMER (FRP)

Advanced Composite FRP Roofing Sheets That Meet Your Needs

FIBERGLASS REINFORCED POLYMER (FRP)

![]() Lite brand of translucent fiberglass reinforced polymer (FRP) roofing and wall cladding is specially developed based on the highest quality and technological standards.

Lite brand of translucent fiberglass reinforced polymer (FRP) roofing and wall cladding is specially developed based on the highest quality and technological standards.

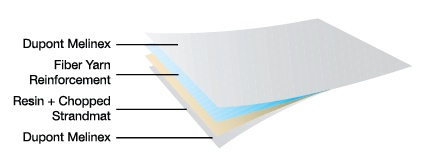

Only the best quality materials are used in our compos ites like non-alkali chopped strand fiberglass mat for added strength, UV inhibitor infused resins for longevity and weathering performance, as well as DuPont Melinex lamination film for a long lasting aesthetic finish.

![]() -Lite translucent FRP sheets come in several grades for different user requirements, from general purpose to fire retardant grades.

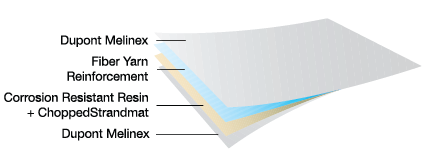

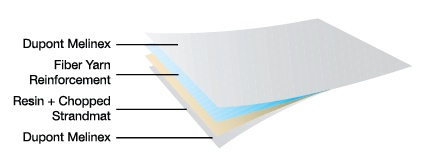

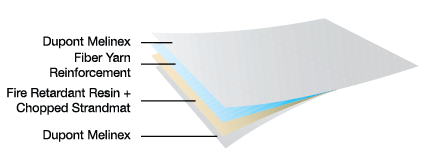

-Lite translucent FRP sheets come in several grades for different user requirements, from general purpose to fire retardant grades.

ADVANTAGES OF USING  LITE FRP TRANSLUCENT ROOFING SHEETS

LITE FRP TRANSLUCENT ROOFING SHEETS

Natural day light saves energy consumption and lighting maintenance. Moreover, it lowers energy consumption.

Lowering heat transmission into building helps create good working atmosphere and energy bill.

Luminance appropriate to activity in the building which may directly affect efficiency and productivity.

Vermax Lite translucent sheets are manufactured from premium raw materials by state of the art machinery.

Manufactured by fully automatic machine with latest technology.

SIRIM tested quality.

Quality raw materials from world renowned sources.

Provide superior light diffusion.

PRODUCT RANGE

| Main Features |

|

|||||

| Application |

Industrial building and warehouses, large stores, stadiums, residential communities and ets | |||||

| Warranty |

Up to 15 years |

|||||

| Main Features |

|

|||||

| Application |

Coastal areas, heavy-polluted and highly corrosive industrial zones | |||||

| Warranty |

Up to 25 years |

|||||

| Main Features |

|

|||||

| Application |

Glass production plants, textile workshops, precision machining factories, light demanding working environments, commercial building. | |||||

| Warranty |

Up to 25 years |

|||||

| Main Features |

|

|||||

| Application |

Steel plants, blast furnaces and other factories that needs to meet fire retardant requirements |

|||||

| Warranty |

Up to 15 years |

|||||

| Product Category |

|

|

|

|

||||||||||||||||||||

| Description |

Weather resistant, high durability, good impact resistance and high light transmission rate |

Weather resistant, high durability, high toughness and high light transmission |

Weather resistant, high durability and toughness, soft lighting and no flare, comfortable light environment | Weather resistant, high durability, good impact resistance and high light transmission rate |

||||||||||||||||||||

| Coating |

Dupont Melinex 301 Anti-aging film |

Dupont Melinex 389 film and 200μm Anti-UV gel coat layer | Dupont Melinex 301 Anti-aging film | Dupont Melinex 301 Anti-aging film | ||||||||||||||||||||

| Resin |

Phenylene UP resin | Special reinforced UP resin | UP resin | Reactive flame retardant resin | ||||||||||||||||||||

| Fibreglass Content |

≥30% | ≥30% | ≥30% | ≥30% | ||||||||||||||||||||

| Nominal Thickness |

1.2mm, 1.5mm, 2.0mm, 2.3mm, 2.6mm, 3.0mm | 1.2mm, 1.5mm, 2.0mm, 2.3mm, 2.6mm, 3.0mm | 1.2mm, 1.5mm, 2.0mm, 2.3mm, 2.6mm, 3.0mm | 1.2mm, 1.5mm, 2.0mm, 2.3mm, 2.6mm, 3.0mm | ||||||||||||||||||||

| Heat Resistance limit |

-40°C ~ +130ºC | -60°C ~ +140ºC | -40°C ~ +130ºC | -40°C ~ +130ºC | ||||||||||||||||||||

| Oxygen Index |

N/A | N/A | N/A | N/A | ||||||||||||||||||||

| Light Transmittance |

|

|

|

|

||||||||||||||||||||

| Anti-Ultraviolet Rate |

≥99% | ≥99% | ≥99% | ≥99% | ||||||||||||||||||||

| Thermal Expansion Coefficient |

2.1, 10¯⁵ m/m°C | 2.1, 10¯⁵ m/m°C | 2.1, 10¯⁵ m/m°C | 2.1, 10¯⁵ m/m°C | ||||||||||||||||||||

| Flexural Strength |

190MPa | 190MPa | 190MPa | 198MPa | ||||||||||||||||||||

| Tensile Strength |

103MPa | 103MPa | 103MPa | 105MPa | ||||||||||||||||||||

| Density | 1.4g/cm³ | 1.4g/cm³ | 1.4g/cm³ | 1.48g/cm³ | ||||||||||||||||||||

| Barcol Hardness |

50 | 50 | 50 | 50 | ||||||||||||||||||||

| Heat Distortion Temperature |

168ºC | 170ºC | 168ºC | 168ºC | ||||||||||||||||||||

| Thermal Conductivity |

0.158W/M.K | 0.158W/M.K | 0.158W/M.K | 0.158W/M.K | ||||||||||||||||||||

| Series |

Thickness |

| 1800gsm | 1.2mm |

| 2400gsm | 1.5mm |

| 3050gsm | 2.0mm |

| 3660gsm | 2.3mm |

| 4270gsm | 2.6mm |

| 4880gsm | 3.0mm |

INSTALLATION GUIDE

INSTALLATION GUIDE

Handling and Storage

Transport and storage Vermax® Lite Roofing Sheets horizontally on flat.

Avoid storing unwrapped Vermax® Lite Roofing Sheets.

Short Vermax® Lite Roofing sheets should be stacked on top of longer ones. Do not stack up more than 1 meter in height.

Store Vermax® Lite Roofing Sheets in a cool, dry and shaded place, protected from direct sunlight. Avoid covering the stacks of Vermax® Lite Roofing Sheets with dark or heat absorbing materials or objects, to prevent solar heat build-up.

Recommended handling:

Protect the sheets from any physical damage.

Avoid stepping on the panel when it on the ground.

Avoid folding panels across the corrugation during handling and installation.

Do not drag the Vermax® Lite Roofing Sheets on the ground or scrape them against structural elements or other rough objects.

Processing

Cutting

Use fine-toothed tenon saw.

Power saws with abrasive cutting-off wheel or circular saw blade suitable for cutting Vermax® Lite Roofing Sheets,

Jig saw with suitable blade may be used as well.

Drilling

a) Pre-drill the required fixing holes to at least 4-5 mm larger than the diameter of the screw used. (e.g. Diameter of screw 4mm, hole drilled required minimum 8mm or larger)

b) Power drill may be use at LOW SPEED and the drill bit must be ground to suit the Vermax® Lite Roofing Sheets,

Avoid drilling hole by punching.

Drilling vertically at 90 °

Installation Guide

| Building Configuration |

Internal Wall Colour |

Usage % | |

| Light Transmission Rate > 70% |

Light Transmission Rate 50% | ||

| Industrial building (Roof height<15m) | Light |

10% | 19% |

| Dark |

12% | 17% | |

| Industrial building (Roof height>15m) | Light | 12% | 17% |

| Dark | 15% | 21% | |

| Warehouse | Light | 10% | 14% |

| Dark | 12% | 17% | |

| Greenhouse | – | 100% | – |

For reference purpose only. Usage are under normal conditions.

Recommended Thickness and Maximum Span

| Profil rib height (mm) (x) |

Thickness / Purlin spacing | ||

| 1.2mm | 1.5mm |

2.0mm | |

| 20 < x < 45 | 1200mm |

1500mm | 1700mm |

| x > 45 |

1500mm | 1700mm | 1900mm |

In consideration of load and strength requirements, recommended purlin spacing as per table above. This information is for reference only.

Recommended Installation

Roof Details

Pitch

The minimum recommended roof pitch for Vermax® Lite Roofing Sheets application is 6° (10% slope).

For roof pitch less than 10° (1:5.6) apply full sealing system (Neutral Silicone Sealants) on all lapping and drilled holes.

Purlins

Roof purlins must have a level face parallel to the Vermax®Lite Roofing Sheets.

The allowed maximum roof span (purlins distance - center to center) is 1.2 meter.

Positioning

Lay the Vermax® Lite Roofing Sheets to overlap the metal roof panels on both sides. If not feasible - Vermax® Lite Roofing Sheets must underlap the metal roof panels side against the primary direction of wind/rain.

Vermax® Lite Roofing Sheets must be located and installed without any stresses. Do not pull, stretch or force the sheets when the profiles are not perfectly matched.

Overlaps

Recommended longtitude overlap of minimum 300mm above purlin.

Each Vermax® Lite Roofing Sheetsto extend 150mm or over the fixings along the purlin.

Recommended apply two runs of sealing (Neutral Silicone Sealants) on both sides of fasteners line.

Side-laps

Recommended apply sealing (Neutral Silicone Sealants) along the centreline of the corrugation ribs

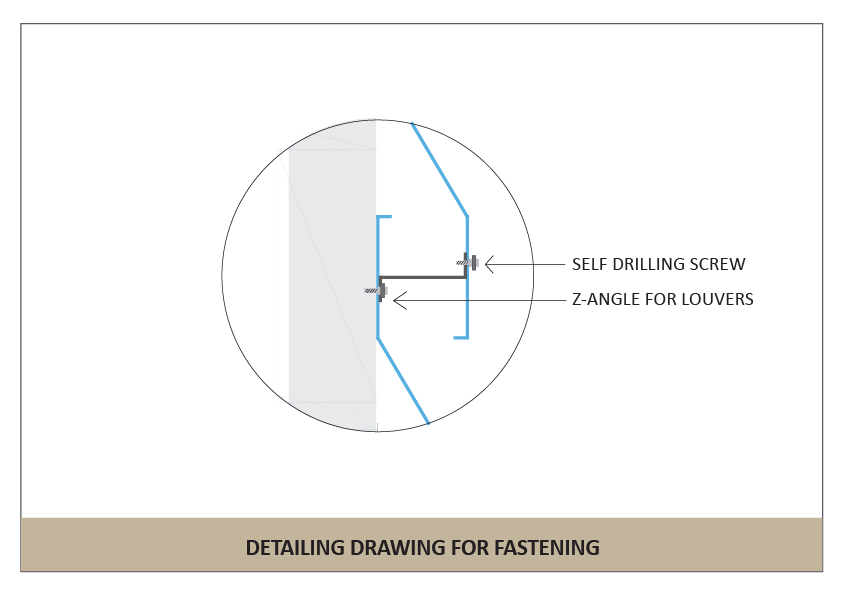

Fastening

Pre-drill 8mm or more holes at the screw points.

Fasten screws on every purlin from the lower end towards the upper end sequentially, starting always from the same side.

Always fasten through the ribs of the Vermax® Lite Roofing Sheets. Do not fasten screw on the valley.

The screws should be tightened moderately, without deforming the washer and distorting the Vermax® Polycarbonate Transparent Roofing Sheets. Careful attention should be given to assure perpendicular insertion of the fasteners.

Excess tightening and oblique insertion will distort the Vermax® Lite Roofing Sheets, induce undue internal stresses, leading to fracture and cracks, eventually ending in failure.

Screws fasten positioning vertically at 90°. Screws fasten position at the center of the pre-drill hole and not the side or corner of the pre-drill hole.

Do not fasten screw at the side or corner of the ribs.

Never use an impact wrench or driver for fastening Vermax® Lite Roofing Sheets. Tighten by handor by an adjustable torque power screwdriver.

Do not use Drive Screw, Nails or Pop Rivets.

TECHNICAL ADVICE:

If you are doubtful over the fixing and installation method, please contact our Project Technician or Marketing personnel for proper advice and assistance.

MANUFACTURER’S LIABILITIES:

The information contained in this brochure is to our best knowledge, accurate and proper, but all the recommendations are made Without Guarantee. Since the conditions of use at work site are beyond our control, we therefore Hold No Liabilities for any mishandling and workmanship defects in using our skylight materials.

PROJECT REFERENCE

Aluminium Factory Extension

Nilai

Factory in Klang

Steel Factory

Kajang

Pulau Indah Warehouse

Logistic Hub

Shah Alam U10

Factory in Seremban

Factory in Melaka

Factory in Melaka

Factory in Melaka

Factory in Melaka

Factory in Klang

Factory in Klang

Factory in Penang

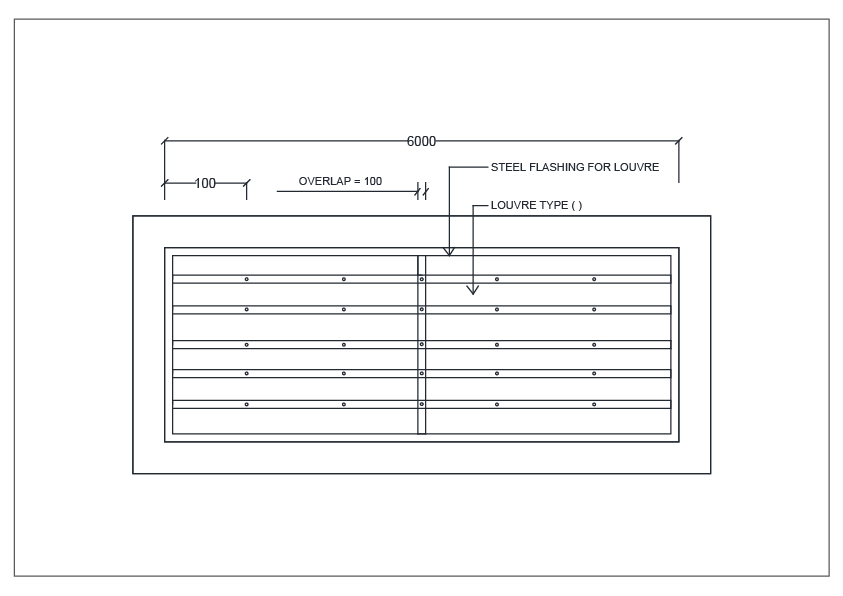

FRP Louvers at Nilai Factory

ADVANCED COMPOSITE FRP LOUVER

Product Specification

Profile Available : Type 400 & Type 600

Color : Blue Translucent, Cream Color

Width : Standard 6meters ( custom sizes available, transport permitting )

Thickness : 1.2mm (1,200 Gram Square Meter)

1.5mm (1,800 Gram Square Meter)

Length : Cut to size-Maximum 6 meter

UV Resistant Rate : 99%

UV Resistant Film : Dupont Melinex

Light Transmission : 75% +/-

Feature & Benefit

Allow air ventilation into buildings

i) Allow beneficial air circulation for large commercial and industrial buildings increasing comfort level and productivity.

Allow natural light into buildings

i) Offer savings from reduced lighting cost and improves indoor air quality.

Wind driven rain resistent design

i) Prevent damages by rain

| APPLICABLE GBI CREDITS |

|||

| NRNC | EQ8 |

NREB | EQ8 |

| RNC |

EQ4 | IEB | EQ9 |

| INC | EQ9 | INTERIORS | EQ6 |

We are green with GBI compliance

i) ASTM D 638 & 1003

ii) ASTM D 790

Ease of Installation

i) ![]() Lite FRP Louvers system can be supplied as fully fabricated louvers frame unit for speedy and easy installation.

Lite FRP Louvers system can be supplied as fully fabricated louvers frame unit for speedy and easy installation.

ALSYNITE TRANSLUCENT SHEET

ALSYNITE closely follow the profile trends of the major steel roofing and cladding manufacturers. As a result, we carry a vast range of profile options within our portfolio. Additionally, new or non standard profiles are easily catered for, with fast lead times for offline samples.

ALSYNITE’s commitment to exacting standards is fully supported by a comprehensive range of performance warranties and technical literature. Offering “peace of mind” to designers, builders and the end user, our performance warranties and technical support covers the complete range of Alsynite products. Inclusive in our technical support, are profiles data sheets, windload charts, installation recommendations and general specification detail.

ALSYNITE’s industrial fibreglass range is strongly supported by a variety of domestic grade profiles and flat panels for various architectural and signage applications. Additionally, we manufacture a comprehensive range of booth industrial and domestic roof ventilators.

ALSYNITE® EVERLITE R74

General Purpose Industrial Translucent Sheet

ALSYNITE EVERLITE R74 is a high quality general purpose FRP that has been the cornerstone of Alsynite’s fibreglass business for many years. Both the exposed and the underside surfaces are protected by a surface coating films produced by world renowned film makers.

This proven system is backed by a 10 years performance warranty.

Available is a wide range of profiles, ALSYNITE EVERLITE R74 is the sensible choice for cost effective skylight and wall applications.

| Key Properties |

|

| Application |

|

SPECIFICATIONS

| Profiles | Due to Alsynite’s global presence, we have an extensive range of profiles within our portfolio that matches most metal sheeting profiles. |

| Sheet Length |

|

| Weight |

1800gsm, 2400gsm, 3050gsm, 3660gsm, 4880gsm |

| Thickness |

1.2mm, 1.5mm, 2.0mm, 2.5mm (±15%) |

| Colors |

Clear, Opal |

| Resin System | Advanced general purpose grade orthophthalic polyester. Fire retardant resin systems 50FR and 25HTH are available. |

| Reinforcement | “E” class fibre optic glass, at least 22% |

SOLAR OPTICAL PROPERTIES

| Clear | Opal | |

| Solar Transmittance |

68% | 58% |

| Luminous Transmittance |

67% | 53% |

| Diffused Light Transmission |

74% | 58% |

| Shading Co-efficient |

82% | 71% |

| U-Value (W/m2K) |

5.7 | 5.7 |

| Solar Heat Gain (W/m2) |

560 | 486 |

| Thermal Conductivity |

72% | 62% |

| UV Resistance |

99.9% | 100% |

| Transmittance 380-320nm (UV-A) |

0.04 | – |

| Transmittance 320-280nm (UV-B) |

0.006 | – |

PHYSICAL PROPERTIES

| Specific Gravity (gm/cc) | 1.41 |

| Thermal Expansion 10-5 cm/cm/oC |

2.2 |

| Water Absorption (%) |

0.52 to 0.60 |

| Thermal Conductivity (W/MoK) |

0.158 |

| Heat Distortion Temperature (oC) |

+180 to 200 |

| Operating Temperatures (oC) | -20 to +80 |

MECHANICAL PROPERTIES

| Barcol Hardness | more than 50 |

| Glass Content (%) |

26.3 |

| Tensile Strength (MPa) |

94 |

| Flexural Strength (MPa) |

177 |

| Flexural Modules (GPa) |

6.7 |

| Mean Impact Strength (J) | 8.9 |

| Compressive Strength (MPa) | 135 |

| Shear Strength (MPa) | 90 |

| Impact Resistance | Pass |

Results of tests are based on a 2400gsm sheet.

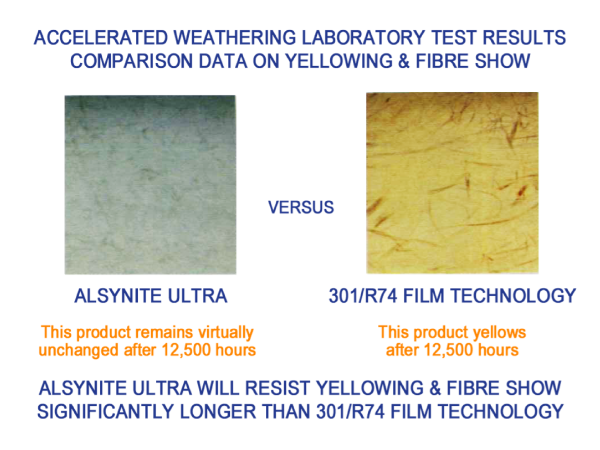

ALSYNITE® ULTRA

Long Term Weathering Properties with UV Surface Protection Film

ALSYNITE ULTRA is a premium quality Fibre Reinforced Polyester (FRP) sheet with excellent long term weathering properties. The exposed surface features a new improved ultra-violet surface protection film. Together with a unique polyester resin formulation, our advanced system is proudly backed by a 25 years performance warranty.

Available in a wide range of profiles, weights and colors, ALSYNITE ULTRA is the premium choice for roofing and wall cladding applications.

| Key Properties |

|

| Application |

|

SPECIFICATIONS

| Profiles | Due to Alsynite’s global presence, we have an extensive range of profiles within our portfolio that matches most metal sheeting profiles. |

| Sheet Length |

Ma 11.9m |

| Weight |

2400gsm, 3050gsm, 3660gsm |

| Thickness |

1.5mm, 2.0mm, 2.5mm (±15%) |

| Colors |

Clear, Opal |

| Resin System | Advanced general purpose grade orthophthalic polyester. Fire retardant resin systems 50FR and 25HTH are available. |

| Reinforcement | “E” class fibre optic glass, at least 22% |

SOLAR OPTICAL PROPERTIES

| Clear | Opal | |

| Thermal Conductivity |

72% | 62% |

| UV Resistance |

99.9% | 100% |

| Diffused Light Transmission |

74% | 55% |

| Solar Heat Gain (W/m2) |

560 | 486 |

| Transmittance 380-320nm (UV-A) |

0.04 | – |

| Transmittance 320-280nm (UV-B) |

0.006 | – |

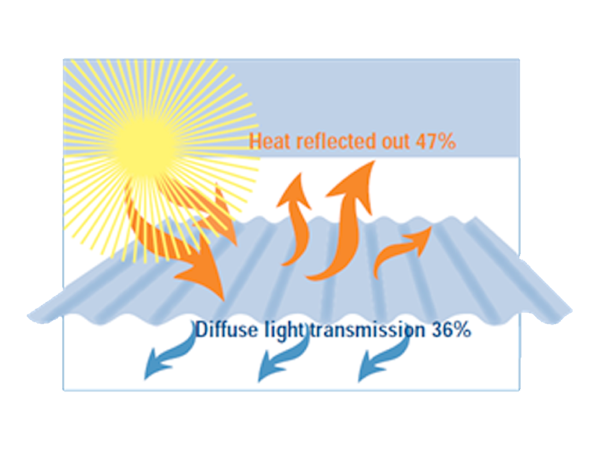

ALSYNITE® ULTRA-COOL

Controlled Solar Heat Transmission

ALSYNITE ULTRA-COOL is a premium quality Fibre Reinforced Polyester (FRP) sheet with all the qualities of ALSYNITE ULTRA, but with the added advantages of controlled solar heat transmission. It is identified by its ultra-white finish.

ALSYNITE ULTRA-COOL provides an economical means of transmitting diffused natural light to the building interior, whilst at the same time reflecting unnecessary solar heat, resulting in substantial cost savings in lighting and cooling expenses.

| Key Properties |

|

| Application |

|

SPECIFICATIONS

| Profiles | Due to Alsynite’s global presence, we have an extensive range of profiles within our portfolio that matches most metal sheeting profiles. |

| Sheet Length |

Standard 11.9m |

| Weight |

2400gsm, 3050gsm, 3660gsm |

| Thickness |

1.5mm, 2.0mm, 2.5mm (±15%) |

| Colors |

Ultra-white |

| Resin System | Advanced general purpose grade orthophthalic polyester. Fire retardant resin systems 50FR and 25HTH are available. |

| Reinforcement | “E” class fibre optic glass, at least 22% |

SOLAR OPTICAL PROPERTIES

| Ultra-White | |

| Solar Transmittance |

22% |

| Luminous Transmittance |

18% |

| Diffused Light Transmission |

36% |

| Shading Co-efficient |

33% |

| U-Value (W/m2K) |

5.7 |

| Solar Heat Gain (W/m2) |

227 |

| Thermal Conductivity |

– |

| UV Resistance |

100% |

| Transmittance 380-320nm (UV-A) |

– |

| Transmittance 320-280nm (UV-B) |

– |

ALSYNITE® FR GRADE

ALSYNITE 50FR AND 25HTH

Fire Retardant FRP Sheet

The Alsynite range of 50FR and 25HTH resin system can be applied to the full range of Alsynite profiles in line with standard nominal weights. Typically, any of the Alsynite surface coating systems (R74, Ultra, Ultra-Cool) are fully compatible with 50FR and 25HTH fire retardant resin systems.

ALSYNITE 50FR

ALSYNITE 50FR, a fire retardant FRP which produces natural lighting for commercial and industrial premises. The polyester resin in 50FR allows compliance with various state building regulations at minimal additional costs. ALSYNITE 50FR is extremely versatile and can be supplied in almost all of Alsynite’s fibreglass range. The 50FR resin system significantly improves weathering performance and best of all, may be specified in a variety of commercial applications without substantial increases in material costs.

When tested in accordance with AS1530.3 ‘Test for Early Fire Hazard Properties of Materials’ Alsynite 50FR gives the following determinations:

AS1530.3 TEST RESULTS

| Ignitability Index | 15 |

| Spread of Flame Index | 9 |

| Heat Evolved Index | 10 |

| Smoke Developed Index | 7 |

ALSYNITE 25HTH

ALSYNITE 25HTH fire retardant resin system in has been specifically formulated for industrial and commercial applications. The 25HTH sheet can be translucent or opaque. ALSYNITE 25HTH resin system incorporates a specific fire retardant formulation.

SPECIFICATIONS

| Profiles | Both surfaces are MelinexR74 protection surface coating system developed by DuPont and is 20 micron nominal thickness. |

| Sheet Length |

Standard 11.9m |

| Weight |

2400gsm, 3050gsm, 3660gsm |

| Thickness |

1.5mm, 2.0mm, 2.5mm (±15%) |

| Colors |

Ultra-white |

| Resin System | Fire retardant resin |

| Reinforcement | “E” class fibre optic glass, at least 22% |

SOLAR OPTICAL PROPERTIES

| Clear | Opal | |

| Heat Transmittance |

74% | 58% |

| UV Resistance |

99.9% | 100% |

| Diffused Light Transmission |

72% | 62% |

PHYSICAL PROPERTIES

| 50FR | 25HTH | |

| Operating Temperatures (°C) |

-40 to +120 | -30 to +110 |

| Oxygen Index |

more than 30 | more than 26 |

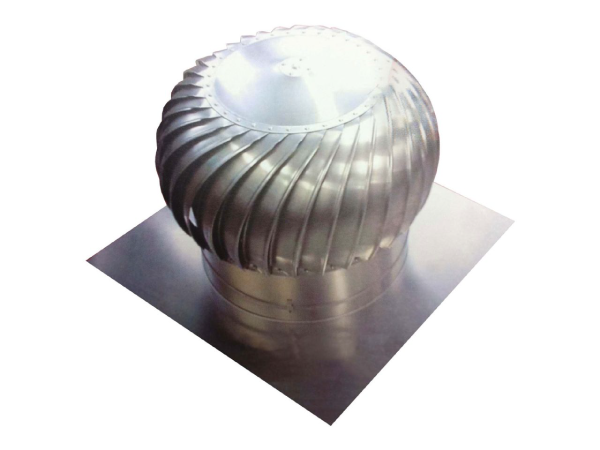

INDUSTRIAL ROOF VENTILATORS

To keep air circulation at a comfortable temperature within an industrial building can be difficult and expensive. ALSYNITE ROOF VENTILATORS are the inexpensive, reliable and effective ventilation solution. Our roof ventilators have been designed to meet wind speeds of 200 km/hr and to the entry of wind-driven rain at a range of 2.5 l/sec under cyclonic conditions. Economically priced, the ROOFVENT is maintenance free and rotates freely and reliably due to the quality bearing system employed. The variable pitch base also allows rapid installation as one size fits most industrial roof pitch angles.

| Key Properties |

|

| Benefits |

|

SPECIFICATIONS

| Roofvent 300 | Roofvent 500 | Roofvent 600 | |

| Diameter of Varipitch (mm) |

300 | 500 | 600 |

| Height of Varipitch (mm) |

190 | 190 | 215 |

| Height of Ventilator (mm) |

450 | 525 | 625 |

| Vent Head (mm) |

430 | 635 | 750 |

| Base Flashing (mm) |

400 x 420 | 750 x 800 | 800 x 850 |

| Number of Vanes |

21 | 32 | 32 |

Calculating the Number of Ventilators Required

- Determine the Volume (VOL) of the building in cubic metres: (Length x Width x Height)

- Dependent on the building type, select the required Air Changes (A/C) per hour from the table below.

- From local authority records, determine the typical wind speed 6, 12 or 16 km/h. This will establish the exhaust capacity litres per second (refer to table).

- Calculate:

RECOMMENDED AIR CHANGES (A/C) FOR VARIOUS BUILDING TYPES

| Warehouses | 5 to 8 A/C/Hour |

| Factories and Workshops |

5 to 10 A/C/Hour |

| Gyms, Tennis & Squash Courts |

5 to 10 A/C/Hour |

| Assembly Halls |

10 to 15 A/C/Hour |

| Garages |

10 to 15 A/C/Hour |

| Toilets | 12 to 15 A/C/Hour |

| Laundries | 12 to 20 A/C/Hour |

| Stables, piggeries & poultry | 10 to 50 A/C/Hour |

PERFORMANCE TABLE

(EXHAUST CAPACITY IN LITRES PER SECOND AT WIND SPEED KM/H)

| 500 | 600 | |

| 6 km/h |

530 | 620 |

| 12 km/h |

870 | 1104 |

| 16 km/h |

1090 | 1420 |